In reinforced concrete structures, the commonly used anchorage method of reinforcement is the structure with hook at the end. Although 90 ° or 135 ° hook reinforcement enhances the anchorage performance of reinforcement and reduces the anchorage length to a certain extent, the structural requirements of bending or large arc radius often bring many problems, such as crowded reinforcement in the beam column joint area, The bending or hook interferes with the arrangement of other reinforcement, and the component size can not meet the requirements of anchorage length, etc. These contradictions are more prominent when using large-diameter reinforcement. The reinforcement mechanical anchorage technology can well solve this problem. On the basis of ensuring the mechanical anchorage performance of reinforcement, the reinforcement anchorage conditions are optimized, the reinforcement anchorage length is reduced, the anchorage steel is saved, the construction is convenient, and the concrete pouring quality is improved. At the same time, mechanical anchoring of reinforcement is also an indispensable product technology for building industrialization and reinforcement component construction.

Application field

- Instead of the traditional bending reinforcement, it is used for beam column joints of frame structures;

- Replace the traditional bending bar and stirrup for simply supported beam support;

- It is used for reinforcement anchorage of various concrete structure projects such as bridges, hydraulic structures, subways, tunnels and nuclear power plants;

- The anchorage of reinforcement bending bars of (construction, reinforcement) parts in building industrialization;

- Used as reinforcement anchor rod (or tie rod) Fasteners for.

workmanship

Reinforcement end cutting

Rib stripping and wire rolling at the end of reinforcement

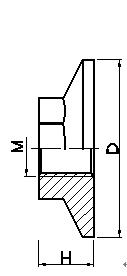

Install the anchor plate

Product advantages

- Safe and reliable - good anchoring performance, which can give full play to the strength of reinforcement and is conducive to the use of higher strength reinforcement;

- Simple and efficient - the process is simple and the work efficiency is high. The nut and gasket are combined into one, which is connected with the straight thread of the reinforcement. The operation is convenient and speeds up the construction speed of the reinforcement project;

- Energy saving and consumption reduction --- it can reduce or cancel the anchorage length of reinforcement, save 40-50% of anchorage steel and reduce the cost of reinforcement;

- Improve quality - overcome the problems of traditional bending bar anchorage crowding and concrete pouring difficulties, and improve the project quality;

- Broad prospects --- it is one of the ten new technologies popularized and applied in the construction industry and one of the applicable technologies for green buildings in Beijing;

Classification and specification of reinforcement anchor plate

| Classification |

Processing mode |

Ratio of bearing area of anchor plate to nominal area of reinforcement |

Anchorage bearing capacity |

| Partial anchor plate |

Casting / forging |

>4.5 |

Bonding force between reinforcement and concrete in anchorage section + local bearing pressure of concrete under anchorage plate |

| Full anchor plate |

Casting / forging |

>9.0 |

All rely on the local bearing capacity of the concrete under the anchor plate

|

五隆兴科技发展有限公司

五隆兴科技发展有限公司