For the connection between reinforcement and section steel column, the quality control problems caused by connection will be encountered in many large public construction projects, as follows;

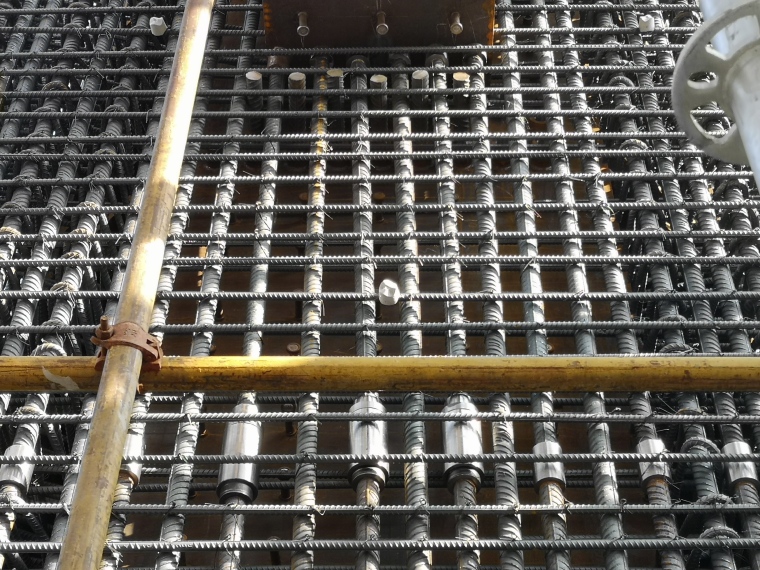

Figure 1: One end of the reinforcement is processed with straight thread and effectively connected with the section steel column through the welding sleeve. It has the advantages of convenient and fast, simple operation, stable and controllable quality, high efficiency and low cost.

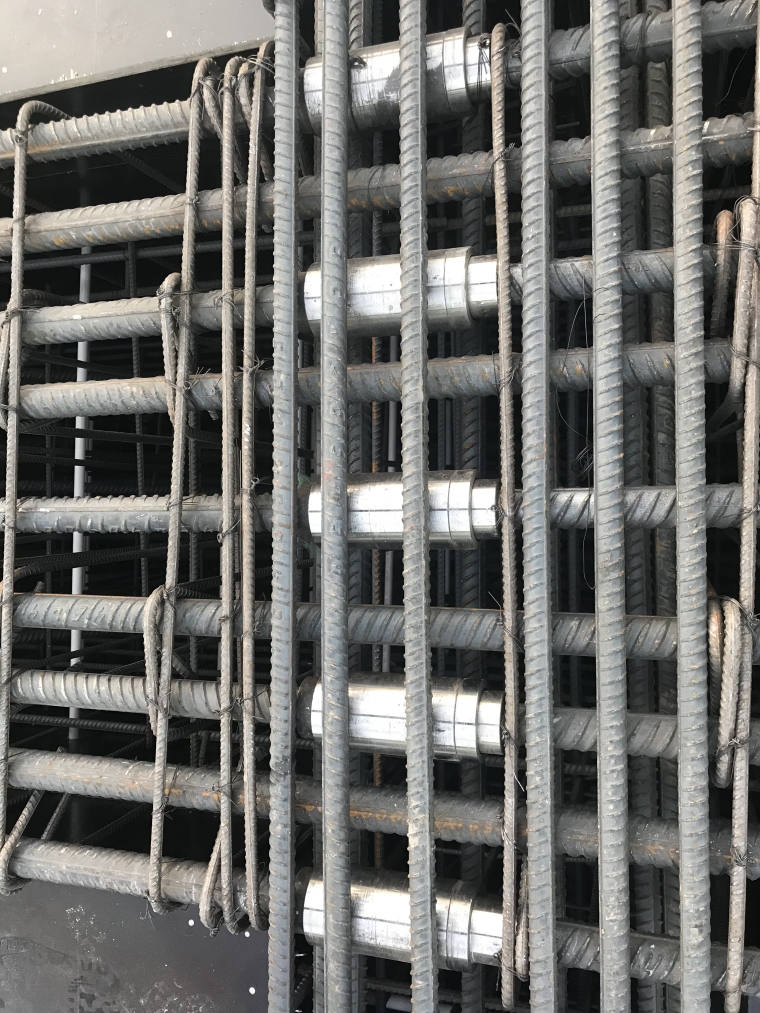

Figure 2: because the reinforcement at the other end cannot rotate, the connecting plate welding operation is adopted. The features can solve the problem that the reinforcement can be connected with the section steel column when it cannot rotate, but there are many unqualified items of welding quality, difficult quality control, low connection efficiency, low qualified rate of flaw detection, unstable quality, large weight of connecting plate, high cost and difficult detection.

Figure 3: both ends are connected by welding sleeves. Because the reinforcement cannot rotate again, it is difficult to connect, so welding connection is adopted. The welding length loses raw materials, the welding quality is also uncontrollable, the welding operation time is long, the qualification rate is low, the efficiency is low, the flaw detection can not guarantee 100% qualification, and the detection cost is high, and the construction progress is difficult to guarantee.

Figure 4: a new type of fabricated mechanical connection process. The section steel and steel column are connected by welding sleeve. For the non rotating parts in the middle, the new mechanical connection method is adopted to connect the two non rotating reinforcement in situ. The connecting reinforcement will not produce displacement during connection, and only a connecting wrench is required for operation. The connection speed is one minute to complete the operation (the reinforcement is also a straight thread thread head), the on-site components are cut to reach the first-class joint strength, the batch connection quality is very stable, the operation time is greatly reduced, and the operability of quality acceptance is strong. There is no open fire operation on site, which greatly saves welder operation and cost.

Figure 5: the vertical reinforcement is connected with the section steel beam. Similarly, the upper and lower reinforcement can complete the in-situ connection through the rotating sleeve when they cannot rotate.

Figure 6 perfect combination of straight thread and new sleeve, each application has its own advantages, reducing cost and increasing efficiency.

五隆兴科技发展有限公司

五隆兴科技发展有限公司![[stiff column] the performance of double screw sleeve instead of welding is incredible! [stiff column] the performance of double screw sleeve instead of welding is incredible!](https://www.bjwlx.com/en/wp-content/uploads/2021/08/1-150x150.png)