钢筋剥肋直径的偏差

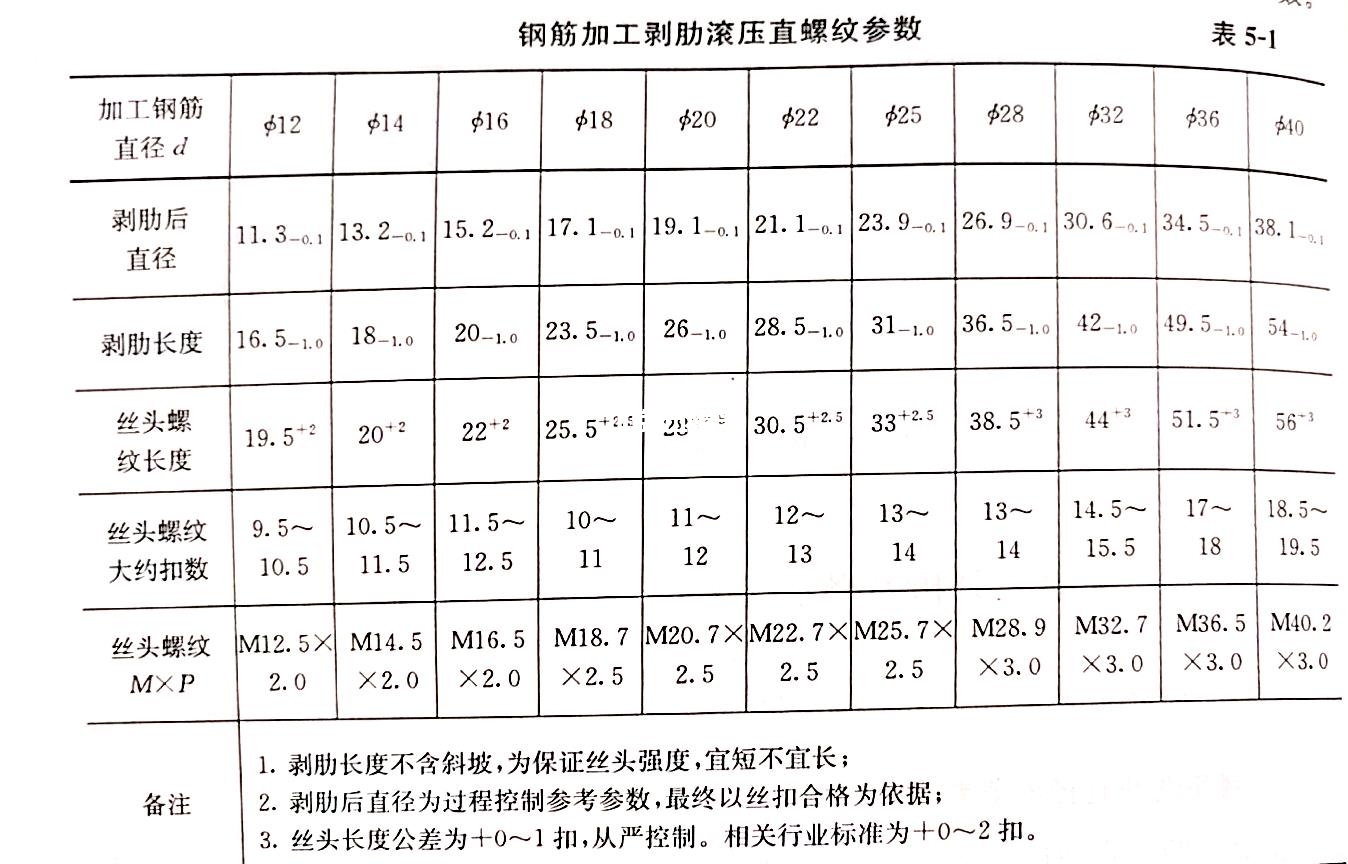

The diameter dimension after rib stripping of reinforcement is an intermediate process value (Table 5-1). Generally, this dimension is the diameter dimension of reinforcement base circle. If this dimension is not well controlled and the processing deviation is large, it will also directly affect the subsequent wire head rolling dimension.

(1) If the rib stripping diameter is too large (the transverse and longitudinal ribs on the reinforcement surface are not completely removed), burr may appear on the thread of the thread head after rolling, and the tooth shape finish will be reduced. At the same time, because the wire rolling diameter has been set, the excessive rib stripping diameter of the reinforcement will increase the pressing amount of the wire rolling wheel and reduce the service life of the roller;

(2) If the diameter of rib stripping is too small, the tooth shape of silk head will not be full, and the possibility of bald teeth at the tip of silk head will increase.

Deviation of rib stripping length of reinforcement

(1) Rib stripping length deviation

The rib stripping length of the reinforcement shall be consistent with the length of the rolling wire. Too long rib stripping will damage the base metal of the reinforcement. Since the rib stripping at this part has not been strengthened by rolling, it is likely to be damaged in this section under the tensile state of the joint, affecting the strength of the joint;

(2) Rib stripping length is short

If the rib stripping is too short, it will affect the rolling quality of each part of the screw head. Does the overall taper of the reinforcement screw head increase, and then affect the thread fit between the screw head and the sleeve.

Deviation of nominal size of steel wire head

(1) Rib stripping length

The rib stripping length of the reinforcement shall be consistent with the length of the rolling wire. Too long rib stripping will damage the base metal of the reinforcement. Because the rib stripping at this part is not strengthened by rolling, it is likely to be damaged in this section and affect the strength of the joint under the tensile state of the joint;

(2) Rib stripping length is too short

If the rib stripping is too short, it will affect the wire rolling quality at the root of the wire head, increase the overall taper of the reinforcement wire head, and then affect the thread fit between the wire head and the sleeve.

Deviation of nominal size of steel wire head

After processing, the reinforcement wire shall be tested with a special thread ring gauge. The ring gauge shall be open and closed at both ends. The qualified screw head can be rotated smoothly, such as the through end of the ring gauge, and 0 ~ 3 BUCKLES shall be exposed by hand;

(1) If the screw head is too large, it will not rotate smoothly into the sleeve;

(2) If the screw head is too small, the fit gap between the screw head and the sleeve increases, so as to reduce the shear capacity of the screw teeth.

Deviation of effective thread length of screw head

The effective length of the screw head is consistent with that of the sleeve thread, with a tolerance of 0 ~ + 1p.

(1) The length of the screw head is too long, which will lead to more exposed threads after the screw head is tightened, and the joint is easy to break at the exposed thread when being pulled;

(2) If the length of the screw head is too short, the matching length with the sleeve cannot be reached, and the joint strength will be affected.

The appearance of thread head profile is unqualified

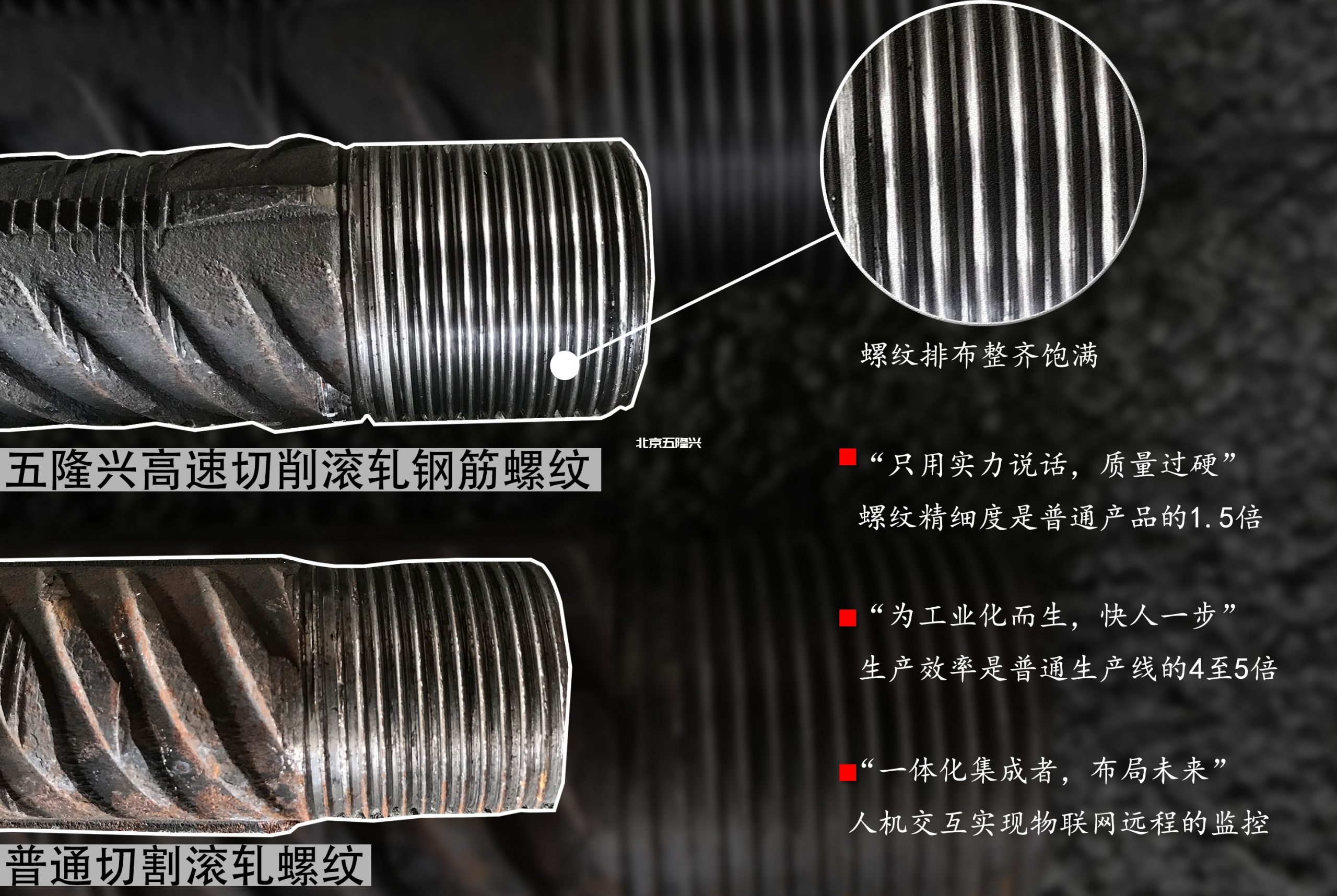

The steel wire head shall meet the accuracy requirements of grade 6F. Within the effective length of the thread, the cumulative number of bare teeth or broken threads shall be more than 2 turns, with low tooth profile finish and rough tooth profile.

Insufficient joint connection

The screw head cannot be screwed into the sleeve completely, resulting in insufficient thread matching length and affecting the connection strength.

五隆兴科技发展有限公司

五隆兴科技发展有限公司![[stiff column] the performance of double screw sleeve instead of welding is incredible! [stiff column] the performance of double screw sleeve instead of welding is incredible!](https://www.bjwlx.com/en/wp-content/uploads/2021/08/1-150x150.png)