With the development of China’s economy and the acceleration of highway and bridge construction, a series of quality accidents have also occurred in highway and bridge engineering, which is directly related to people’s property safety and has become the focus of attention. Highway and bridge construction units should attach great importance to this. The concealment of bridge pile foundation construction requires that in the construction of bridge pile foundation, we should not only rely on advanced science and technology, but also deal with the problems in the construction in time according to rich construction experience, so as to avoid the occurrence of engineering quality accidents. According to the specific geological conditions of the project, the pile foundation construction generally adopts the excavation pile construction. Bored cast-in-place pile shall be used for construction in geology that is not easy to excavate. As the bored cast-in-place pile in bridge engineering is a concealed project, most of the work is carried out underwater, and the construction quality inspection is difficult. Therefore, discussion on bored pile construction technology in bridge engineering is of great significance

-

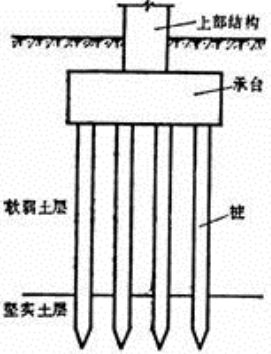

The pile foundation is composed of several piles and pile top bearing platform A common deep foundation. When the position of pier and abutment is weak When the overburden is thick and the bearing stratum is deep, the pile foundation can It passes through the weak layer and is supported on the supporting rock layer. Bridge pile Most foundations are reinforced concrete piles.

- According to the stress form, the pile foundation can be divided into end bearing pile and friction pile. The bearing capacity of the former is mainly provided by the rock stratum at the bottom of the pile, and the latter is provided by the vertical friction force of the pile through the soil layer.

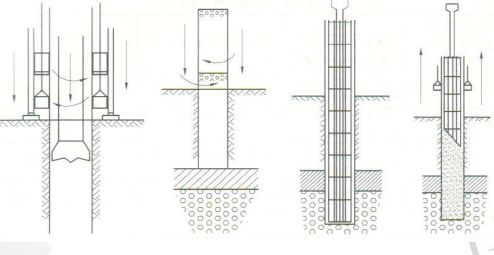

- Pile foundation construction methods can be divided into two categories: cast-in-place pile and sunk pile.

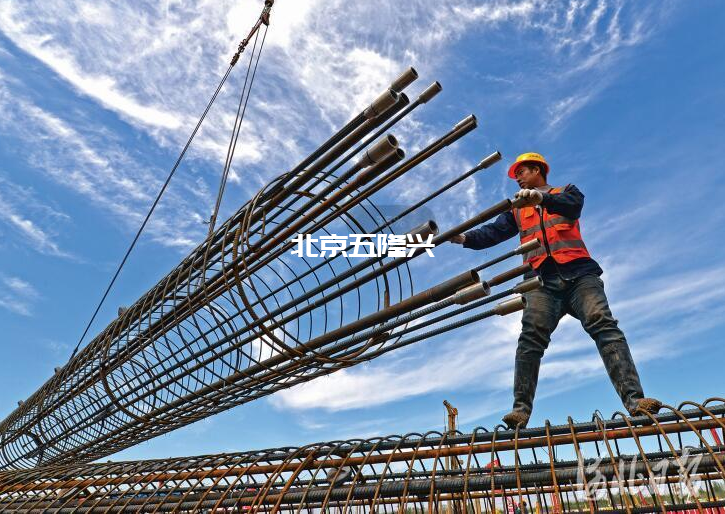

- The construction of cast-in-place pile is to make a pile hole in the soil manually or mechanically, then put the reinforcement cage of the pile body into the pile hole, pour concrete into the hole to form a pile, and finally pour tie beam or bearing platform at the top of the pile. If the pile hole is excavated manually, it is called hole digging pile, and if the hole is excavated mechanically, it is called bored pile.

- The drilling methods of bored piles mainly include: rotary drilling rig, positive and negative circulation drilling rig, casing drilling rig, impact drilling rig, etc.

- The construction of cast-in-place pile is to make pile holes in the soil manually or mechanically, and then Then put the reinforcement cage of the pile body into the pile hole, pour concrete into the hole to form the pile, and finally pour tie beam or bearing platform at the top of the pile. If the pile hole is excavated manually, it is called hole digging pile, and if the hole is excavated mechanically, it is called bored pile.

- The drilling methods of bored piles mainly include: rotary drilling rig, positive and negative circulation drilling rig, casing drilling rig, impact drilling rig, etc.

Drilling with rotary drilling rig : The drill rod drives the drill bit to rotate, The forward rotation of the power bit can drill at a low speed, reverse and throw the soil at a high speed. The bit rotates to cut the soil or sand into ballast soil, and then quickly put it out of the hole. This method can realize dry construction without mud mucking and has good environmental protection. It is suitable for clay, silt, sandy soil, muddy soil and some pebble gravel strata.

Percussion drilling : The percussion drill is to raise the heavy bit with edge or punch and grasp with winch and other equipment, and then release the winch, the bit falls down, cutting and crushing the rock and soil at the bottom of the hole. After the drill bit is lifted out of the orifice, the slag can be discharged with the slag discharge cylinder, or the slag can be discharged with the mud circulation method. Impact drilling is applicable to a wide range of clay, silt and pebble layers.

Casing drilling : It is to press a steel casing with mechanical shaking while drilling 。 The function of the casing is to prevent the hole from collapsing, and the soil in the hole is removed with a heavy hammer grab. Place the reinforcement cage after the hole is formed, and then gradually pull out the casing when pouring the concrete of the pile body. The casing drilling method is applicable to the covering soil layer of non rock stratum, has good protection against hole collapse, and can be constructed near existing buildings.

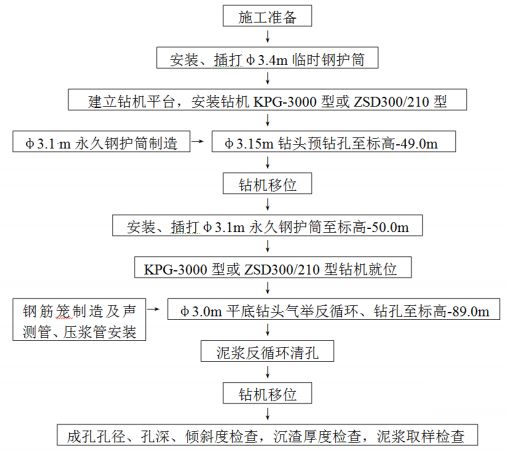

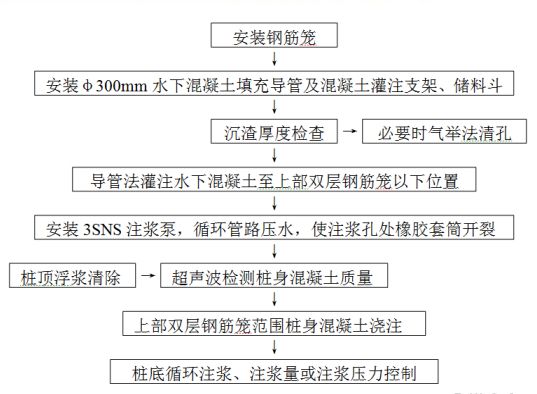

Working procedure

Drilling with forward and reverse circulation drilling rig : Depending on the rotary drilling of the drill bit, the mud circulates in and out of the drilling hole, floats up, and takes the drilling slag out of the drilling hole to realize slag removal. According to the mud circulation method, it can be divided into positive circulation and reverse circulation. The efficiency of reverse circulation method is higher than that of positive circulation method.

At the same time, the slurry can protect the wall (balance the water pressure in the hole) to prevent hole collapse and floating The role of ballast. The mud is composed of clay or expansive soil plus admixtures, and the specific gravity of the mud is generally between 1.1 ~ 1.3.

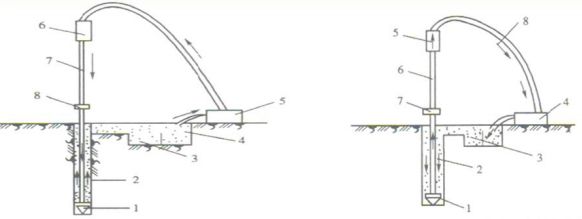

The geological conditions at the bridge site are silty, fine, medium and coarse sand layers and a small amount of gravel layer. The bridge foundation is concrete bored cast-in-place pile, with 4 piles for each pier φ 3.0m bored pile, 10.0m pile spacing along the bridge, 9.0m pile spacing along the bridge, and 91.0m pile length. Considering the serious scouring of riverbed in rainy season, there is a steel casing at the upper part of bored pile, and the steel casing of pier pile is designed as diameter φ 3.0m, casing length 52m.

Characteristic:

From the drilling of the bottom opening of the permanent steel casing to the concrete filling of the permanent steel casing The bottom opening of the barrel shall not exceed 73 hours (39m pile length). Ballast thickness at the hole bottom: the ballast thickness at least 50% of the cross section at the hole bottom is less than 15mm, and the ballast thickness at any position of the hole bottom section is ≯ 40mm. Pile bottom grouting: in order to make the grouting pipeline at the bottom of the reinforcement cage as close to the hole bottom as possible without damage, a bottom touch indicator switch is installed at the bottom of the reinforcement cage.

Construction process 1

Construction process 2

Source of this article: [bridge pile foundation construction] graphic analysis of bridge pile foundation construction technology, only this article- Civil online, civil online helps engineers grow,

https://bbs.co188.com/thread-10197780-1-1.html

五隆兴科技发展有限公司

五隆兴科技发展有限公司

您好!请登录